CONFIGURE YOUR SMALL FOOTPRINT PCNC 440 MILL

Download Technical Specifications

ENTRY PACKAGE

$7,010

Finance with 1/2 price payments for 1/2 a year!

Learn More

- ✔ PCNC 440 base mill

- ✔ PathPilot CNC controller

- Mill stand

- Tooling

- Vise

- Mill enclosure

- Power drawbar

- Automatic tool changer

STARTER PACKAGE

$10,450

Finance with 1/2 price payments for 1/2 a year!

Learn More

- ✔ PCNC 440 base mill

- ✔ PathPilot CNC controller

- ✔ Mill stand

- ✔ Tooling

- ✔ Vise

- Mill enclosure

- Power drawbar

- Automatic tool changer

PREMIUM PACKAGE

$15,216

Finance with 1/2 price payments for 1/2 a year!

Learn More

- ✔ PCNC 440 base mill

- ✔ PathPilot CNC controller

- ✔ Mill stand

- ✔ Tooling

- ✔ Vise

- ✔ Mill enclosure

- ✔ Power drawbar

- Automatic tool changer

AUTOMATIC TOOL

CHANGER PACKAGE

$18,786

Finance with 1/2 price payments for 1/2 a year!

Learn More

- ✔ PCNC 440 base mill

- ✔ PathPilot CNC controller

- ✔ Mill stand

- ✔ Tooling

- ✔ Vise

- ✔ Mill enclosure

- ✔ Power drawbar

- ✔ Automatic tool changer

Not sure which machine is right for you?

Schedule a Pre-Sales ConsultationA COMPACT DESIGN WITH SINGLE-PHASE POWER

The easy-to-use PCNC 440 is a capable mill for education, small manufacturers, hobbyists, and beginners, bringing CNC machining to diverse spaces. The modularity of the single-phase power PCNC 440 allows users to customize their machine as their production needs change, making this an affordable option for those starting out. The PCNC 440 mill cuts through several materials, including aluminum, stainless steel and titanium.

PCNC 440 PERSONAL CNC MILL FEATURES

Cast iron frame and table

Dovetail ways

Plugs into any standard single-phase 120Vac outlet

Ball screws

10,000 RPM R8 spindle

10 in. x 6.25 in. x 10 in. work envelope

42 in × 36 in. machine footprint

The PCNC 440’s compact design makes it easy to set up your own shop.

"It fits perfectly in my single car garage, which has now been transformed into my machine shop. I was shocked that the 440 plugs into a standard wall outlet!” — Joshua Ladlee, Owner of Patient Zero Balisong

KNIFEMAKER USES PCNC 440 TO LAUNCH HIS BUSINESS.

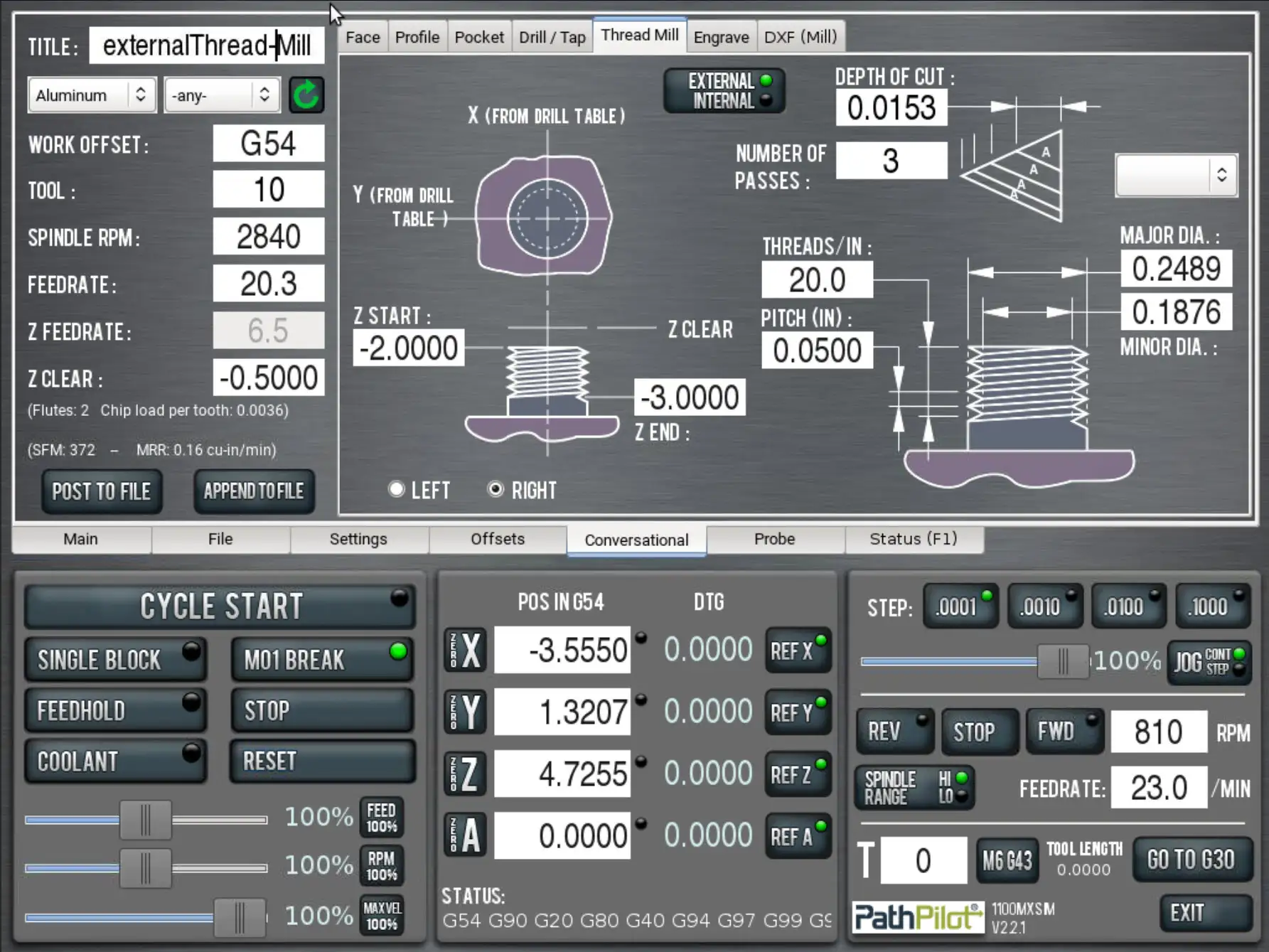

EASY-TO-USE PATHPILOT CONTROL SOFTWARE

PathPilot® is the exclusive CNC controller of Tormach and is included on all machines for free. PathPilot features easy-to-use conversational software that allows you to edit programs on the fly. You can sharpen your programming skills on the PathPilot HUB, which allows you to test out PathPilot online. Learn how to program and create usable G-Code. Log in today to create your free membership.

SHOW ME MORE ABOUT PATHPILOT

Looking For Help With Your PCNC 440 Mill?

Visit the Tormach Support Site to find Manuals, Technical Documents, Datasheets, Service Bulletins,The Knowledge Base and Troubleshooting Guides.

View Support Section